MeSy - Determination of in-situ rock stresses

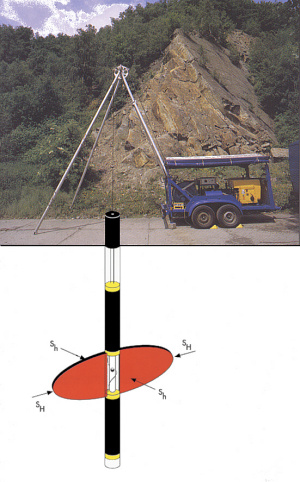

Knowledge of the in-situ primary stresses in the subsurface is a prerequisite for the planning of underground structures with regard to their dimensioning and long-term stability. The only method for direct measurements of in-situ stresses are the hydraulic fracturing (HF) or hydraulic testing of pre-existing fractures (HTPF) methods.

Hydraulic Fracturing (HF) or Hydraulic Testing of Pre-Existing Fractures (HTPF)

For this method, a very small volume of fresh water without chemical additives is pumped into the rock to open microcracks. Hydraulic fracturing (HF) or hydraulic testing of pre-existing fractures (HTPF) is not to be confused with fracking for the extraction of unconventional shale and coal seam gas deposits, where the hydrocarbon reservoir is stimulated using large fluid volumes.

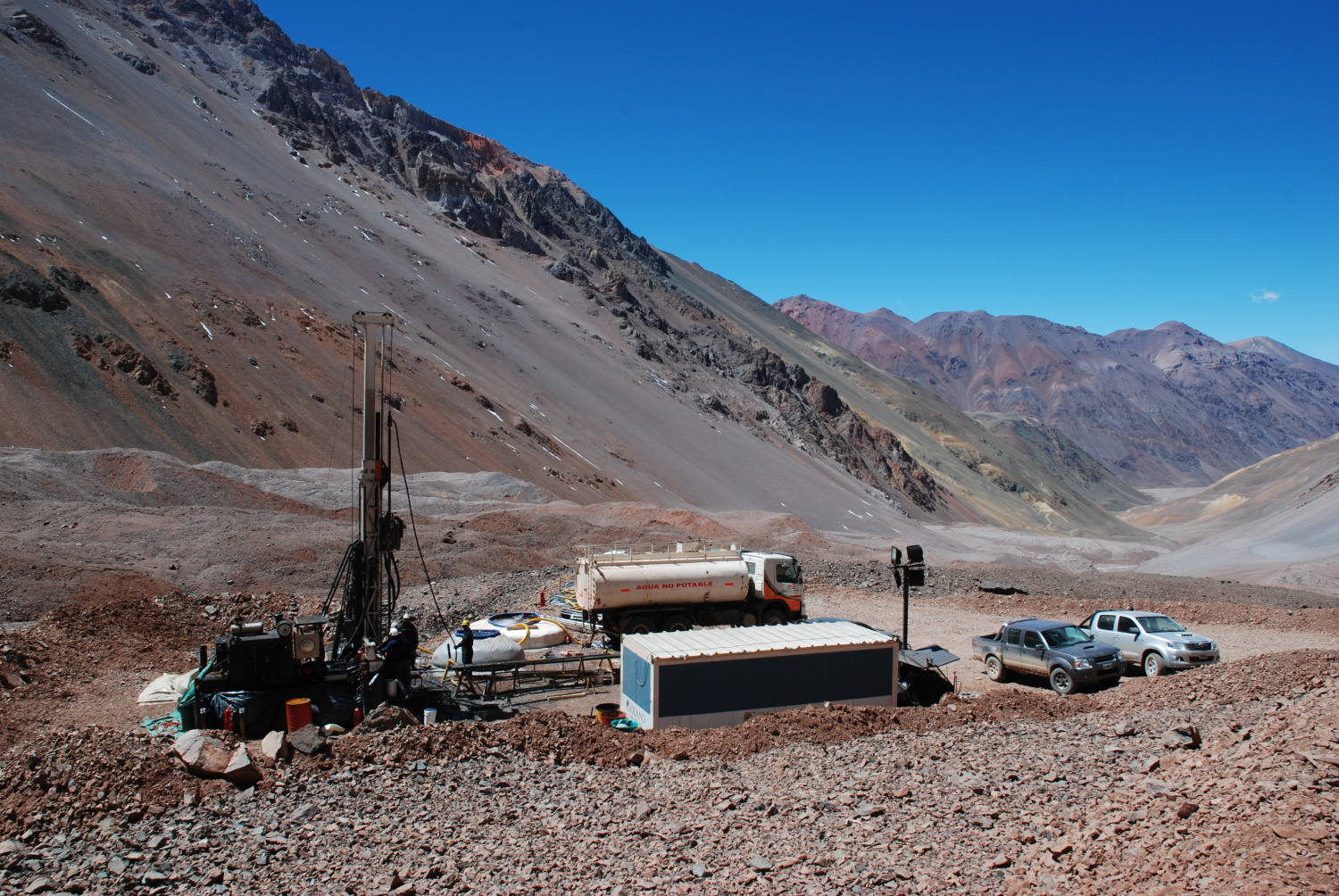

Solexperts, together with its subsidiary Solexperts GmbH, Bochum, has many years of experience in the field of in-situ stress measurement in boreholes up to 5 km depth for every common borehole diameter. In addition to conventional testing on drill pipe or tubing string, the tests are mainly carried out with the wireline equipment developed by us and are therefore independent of the drilling rig and very cost-efficient.

Laboratory

In addition to the determination of in-situ primary stress measurements, Solexperts GmbH, Bochum, maintains its own rock mechanics and rock physics laboratory that complies with national and international standards. A wide range of laboratory tests can be offered due to the close cooperation with the engineering geology/rock construction group of the Ruhr University Bochum.

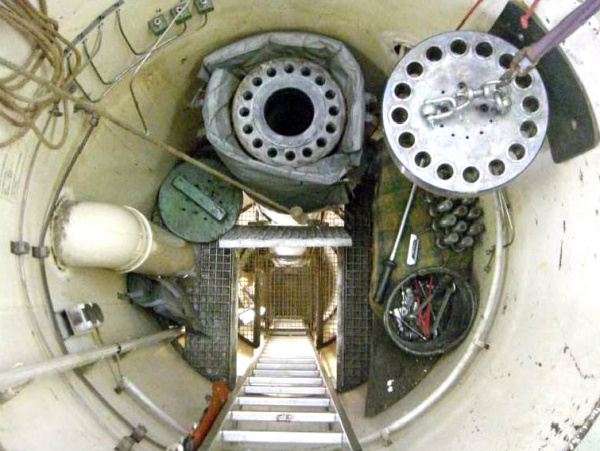

Autoclave

The borehole simulation autoclave developed by Solexperts GmbH, Bochum, is a unique instrument for simulating borehole conditions up to 1500 bar and 200 °C at a diameter of 165 mm with little effort and at low cost. In the autoclave, downhole instruments and drilling tools with lengths of up to 7800 mm can be tested under the conditions under which they will later be used.